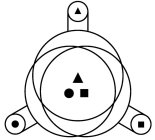

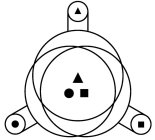

Image Trademark with Serial Number 77234675

Status: 800 - Registered And Renewed

Serial Number

77234675

Registration Number

3448177

Word Mark

Status

800 - Registered And Renewed

Status Date

2018-03-10

Filing Date

2007-07-20

Registration Number

3448177

Registration Date

2008-06-17

Mark Drawing

2000 - Illustration: Drawing or design without any word(s)/letter(s)/ number(s)

Typeset

Design Searches

260102, 260116, 260121, 260131, 260513, 260521, 260913, 260921 - Plain single line circles. Circles touching or intersecting. Circles that are totally or partially shaded. Five or more circles. Two Triangles. Triangles that are completely or partially shaded. Two squares. Squares that are completely or partially shaded.

Published for Opposition Date

2008-04-01

Attorney Name

Law Office Assigned Location Code

M50

Employee Name

ALT, JILL C

Statements

Indication of Colors claimed

Color is not claimed as a feature of the mark.

Description of Mark

The mark consists of Pictorial representation of a circular separator.

Goods and Services

Vibratory screeners for sifting, scalping, classifying, delumping, and dewatering of bulk solids and slurries and separating bulk solid materials from solids and slurries using multi-plane, inertial vibration that causes particles to pass through apertures in the screen or to travel across the screen surface in controlled pathways; Combination vibratory screener, a batch hopper and an integral feed control device regulating the flow of material into the screener for a screening in batches; Batch and continuous single-deck screeners separating solid particles from dry or moist bulk solid material or solids-laden slurries for industrial, food, dairy and pharmaceutical industries; Low profile, high-capacity scalper separating machine; Batch and continuous single and multi-deck vibratory screeners sifting, scalping and classifying dry, moist, lumpy, stringy and otherwise difficult-to-handle bulk material into precise segment particle classifications; Batch and continuous single and multi-deck vibratory screeners with anti-blinding devices for sifting, scalping and/or classifying dry, moist, lumpy, stringy and otherwise difficult-to-handle bulk material into precise segment particle classifications; Batch and continuous single and multi-deck vibratory screeners with hinged lid and frames released via quick-disconnect clamps and held in an open position by gas pistons, allowing rapid screen changes, inspection and easy, thorough wash down of all interior surfaces, for sifting, scalping and classifying dry, moist, lumpy, stringy and otherwise difficult-to-handle bulk material into precise segment particle classifications; Quick Screen Change System for access to the interior of any circular vibratory screener for screen changing, cleaning or inspection; Ultra-Sanitary Screener with gap-free screen frames, quick-release "U" clamps, radius corners, a domed lid, and a lift device to raise the frames, continuous ground and polished welds, a crevice-free interior, and a washable underside Pharmaceutical/Sanitary CIP Sifter; Low-profile, ultra-sanitary batch sifters scalping oversize particles down to 38 microns (400 mesh) from bulk materials; High-capacity classifiers with a coarse upper screen to scalp and a fine-mesh lower screen to dedust for removing oversize particles and fines from plastic pellets, grains, sugar, salt, fertilizer and other materials at ultra-high rates; Internal recycle screening decks for cascading excess material over the periphery of the upper screen into a bowl shaped tray that redirects it into the center of the lower screen for final separation; High-capacity screener scalping dry materials in-line with dilute-phase pneumatic conveying systems at high rates, removing oversize particles and foreign materials from plastic resin, flour, starch, sugar, and numerous food and chemical products, primarily for loading/unloading of trucks or rail cars, or conveying materials between process or storage areas; Dual-screen ultra-high-capacity separator scalps in-line with pneumatic conveying systems gently, at ultra-high rates; Portable batch sifter scalps oversize particles from small batches of bulk material loaded into containers, process equipment and storage vessels; Mobile batch sifter scalps oversize particles from small batches of bulk material loaded into containers, process equipment and storage vessels; Wiper blade assembly mounted on separators and screener for breaking down lumps and preventing screen blinding; Ultrasonic anti-blinding device allowing clog-free, fine-mesh sifting of powders at high rates with no screen blinding; Circular vibratory bag dump screeners scalping bag scraps and other oversize materials from manually dumped bulk materials and protecting the operator and plant environment against dust contamination; Powder coater for coating sticky pellets with non-reactive powder for storage and shipping; Screens for circular vibratory screeners Centrifugal screeners for sifting, scalping, delumping and dewatering of bulk solids and slurries and for screening a wide variety of powders or granular materials, including chemicals, plastics and resins, foods, dairy products, pharmaceuticals and biologicals; Centrifugal screener separating solids from solids or slurries at high rates; Centrifugal screener with anti-blinding devices for separating solids from solids or slurries at high rates; Quick-clean centrifugal screener having a three-bearing shaft that cantilevers on the inboard bearing when the hinged end cover is opened and allowing rapid removal of components for thorough cleaning and maintenance for food, dairy, pharmaceutical and other contamination-sensitive materials; Centrifugal screener, for food, dairy, pharmaceutical and chemical applications requiring thorough wash down, frequent screen changes or runs of multiple materials, with a three-bearing shaft that cantilevers on the inboard bearing when the hinged end cover is open, allowing rapid, tool-free removal of the internals for wash down and screen changes; Centrifugal separator de-lumps and screens materials in-line with dilute-phase pneumatic conveying systems; Centrifugal screeners with an integral bag dump station and dust collector for removing bag scraps and other oversize contaminants from manually dumped bulk materials and protecting the operator and plant environment against dust contamination; Centrifugal dewatering screener for extracting moisture; Miniature centrifugal screener scalping, dedusting, delumping and dewatering small batches of pharmaceutical powders, powder coatings, bulk foods, and other contamination-sensitive products; Fluid bed dryers, coolers and moisturizers for drying, cooling or moisturing of bulk materials; Circular vibratory fluid bed processor for drying, cooling and moisturizing; High temperature fluid bed batch dryer for drying small batches of bulk materials; Circular fluid bed processors drying, cooling or moisturizing bulk foods, pharmaceuticals and chemicals in batch sizes typical of lab and pilot plant applications; Medium capacity fluid bed processing system for drying, cooling or moisturizing bulk material on a batch or continuous basis; Double-deck, circular vibratory fluid bed processor for drying, cooling and moisturizing; Static scalping sieve scalping coarse, free-flowing dry solids at ultra-high rates and continuously removing oversize particles from coarse, free-flowing, dry bulk solids; Static dewatering sieve continuously clarifying high volumes of wastewater and removing solids from waste streams at ultra-high rates; Static dewatering sieve for removing solids from waste streams at ultra-high rates and for clarifying high volumes of industrial or municipal wastewater

Classification Information

International Class

007 - Machines and machine tools; motors and engines (except for land vehicles); machine coupling and transmission components (except for land vehicles); agricultural implements (other than hand-operated); incubators for eggs. - Machines and machine tools; motors and engines (except for land vehicles); machine coupling and transmission components (except for land vehicles); agricultural implements (other than hand-operated); incubators for eggs.

US Class Codes

013, 019, 021, 023, 031, 034, 035

Class Status Code

6 - Active

Class Status Date

2007-07-25

Primary Code

007

First Use Anywhere Date

1966-10-07

First Use In Commerce Date

1966-10-07

Current Trademark Owners

Party Name

Party Type

30 - Original Registrant

Legal Entity Type

03 - Corporation

Address

Please log in with your Justia account to see this address.

Trademark Owner History

Party Name

Party Type

30 - Original Registrant

Legal Entity Type

03 - Corporation

Address

Please log in with your Justia account to see this address.

Party Name

Party Type

20 - Owner at Publication

Legal Entity Type

03 - Corporation

Address

Please log in with your Justia account to see this address.

Party Name

Party Type

10 - Original Applicant

Legal Entity Type

03 - Corporation

Address

Please log in with your Justia account to see this address.

Correspondences

Name

John R. Benefiel

Address

Please log in with your Justia account to see this address.

Trademark Events

| Event Date | Event Description |

| 2007-07-25 | NEW APPLICATION ENTERED IN TRAM |

| 2007-07-26 | NOTICE OF DESIGN SEARCH CODE MAILED |

| 2007-09-23 | ASSIGNED TO EXAMINER |

| 2007-09-24 | NON-FINAL ACTION WRITTEN |

| 2007-09-24 | NON-FINAL ACTION E-MAILED |

| 2007-09-24 | NOTIFICATION OF NON-FINAL ACTION E-MAILED |

| 2007-11-19 | TEAS RESPONSE TO OFFICE ACTION RECEIVED |

| 2007-11-19 | CORRESPONDENCE RECEIVED IN LAW OFFICE |

| 2007-11-19 | TEAS/EMAIL CORRESPONDENCE ENTERED |

| 2007-11-23 | NON-FINAL ACTION WRITTEN |

| 2007-11-23 | NON-FINAL ACTION E-MAILED |

| 2007-11-23 | NOTIFICATION OF NON-FINAL ACTION E-MAILED |

| 2008-01-30 | TEAS RESPONSE TO OFFICE ACTION RECEIVED |

| 2008-01-30 | CORRESPONDENCE RECEIVED IN LAW OFFICE |

| 2008-01-31 | TEAS/EMAIL CORRESPONDENCE ENTERED |

| 2008-02-01 | EXAMINERS AMENDMENT -WRITTEN |

| 2008-02-01 | EXAMINERS AMENDMENT E-MAILED |

| 2008-02-01 | NOTIFICATION OF EXAMINERS AMENDMENT E-MAILED |

| 2008-02-01 | EXAMINER'S AMENDMENT ENTERED |

| 2008-02-01 | APPROVED FOR PUB - PRINCIPAL REGISTER |

| 2008-02-28 | ASSIGNED TO LIE |

| 2008-02-28 | LAW OFFICE PUBLICATION REVIEW COMPLETED |

| 2008-03-12 | NOTICE OF PUBLICATION |

| 2008-04-01 | PUBLISHED FOR OPPOSITION |

| 2008-05-05 | TEAS CHANGE OF CORRESPONDENCE RECEIVED |

| 2008-06-17 | REGISTERED-PRINCIPAL REGISTER |

| 2009-08-26 | TEAS REVOKE/APP/CHANGE ADDR OF ATTY/DOM REP RECEIVED |

| 2009-08-26 | ATTORNEY/DOM.REP.REVOKED AND/OR APPOINTED |

| 2013-06-19 | TEAS SECTION 8 & 15 RECEIVED |

| 2013-07-03 | CASE ASSIGNED TO POST REGISTRATION PARALEGAL |

| 2013-07-08 | REGISTERED - SEC. 8 (6-YR) ACCEPTED & SEC. 15 ACK. |

| 2013-07-08 | NOTICE OF ACCEPTANCE OF SEC. 8 & 15 - E-MAILED |

| 2017-06-17 | COURTESY REMINDER - SEC. 8 (10-YR)/SEC. 9 E-MAILED |

| 2017-11-22 | TEAS SECTION 8 & 9 RECEIVED |

| 2017-12-13 | CASE ASSIGNED TO POST REGISTRATION PARALEGAL |

| 2017-12-14 | POST REGISTRATION ACTION MAILED - SEC. 8 & 9 |

| 2018-01-05 | TEAS RESPONSE TO OFFICE ACTION-POST REG RECEIVED |

| 2018-01-17 | POST REGISTRATION ACTION MAILED - SEC. 8 & 9 |

| 2018-02-25 | TEAS RESPONSE TO OFFICE ACTION-POST REG RECEIVED |

| 2018-03-10 | REGISTERED - SEC. 8 (10-YR) ACCEPTED/SEC. 9 GRANTED |

| 2018-03-10 | REGISTERED AND RENEWED (FIRST RENEWAL - 10 YRS) |

| 2018-03-10 | NOTICE OF ACCEPTANCE OF SEC. 8 & 9 - E-MAILED |